As you know, Federal Regulations require Detectable Warning Panels (DWPs), so they are going to be on EVERYONE of your City/Town, State & Commercial projects where applicable. Sometimes the type of DWP (Cast in Place or Surface Applied) will be specified. But at other times, you will have a choice.

It may seem this is only of value when YOU have a choice between these 2 options. However, the information found here will also be of great value when you are bidding a project. This article should help to refine your bidding, and result in you having a different bid price for each of these types of DWPs.

So read on and make this mandatory item, more profitable than ever.

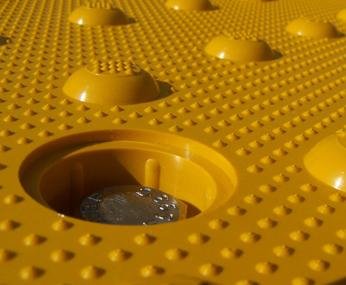

Cast-in-Place Tiles

Cast-in-place ADA tiles are designed primarily for new construction and new concrete surfaces; thus, if you are pouring new concrete on your project where an ADA truncated dome warning system is needed, a cast-in-place tile is the right option for your project. Cast-in-place tiles are ideal for installation in concrete while it is wet, providing long-term stability and durability even under heavy traffic or severe weather conditions. In cases where you are particularly concerned about replacing your ADA tiles in the future, cast-in-place replaceable tiles have a simple replacement procedure built into the product. Replaceable tiles implement a simple bolt system that locks the tile in place inside the surrounding concrete surface. The bolts can be easily accessed and removed to simply lift the old tile away and bolt a new tile in its place, leaving the entire concrete surface intact to save time and money during replacement.

Surface-Applied Tiles

While cast-in-place tiles are ideal for new building projects, both new and existing properties fall under the requirements of the Americans with Disabilities Act. Thus, ADA tiles are often needed in existing areas where replacing concrete is not feasible, necessary, or cost-effective. Surface-applied ADA warning tiles are meant for use on existing concrete in areas that require truncated dome tiles to ensure compliance with ADA Regulations. These tiles are thinner than cast-in-place tiles and can be installed in approximately 10-15 minutes for a fast, simple, and effective way to retrofit existing sidewalks, parking lots, walkways, and other areas. To install surface-applied tiles, a combination of adhesive and fasteners is used to ensure the tile is mounted properly on the ground and prevent tile slippage or separation from the surrounding area for safety and efficacy. Surface-applied tiles can be replaced as necessary by levering or breaking up the damaged tile, cleaning the area, and installing a new tile in its place.

Making the right choice when purchasing ADA truncated dome tiles means enjoying an easy installation and getting the durability and performance from your purchase that you expect. You can find out more about the types of truncated dome warning surfaces we produce and how to make the right selection when you scroll through this website, or by calling us at 888-397-0267

NOW for the $ Comparison

When you have to chose between these 2 applications, or when you are bidding, the following information is SO IMPORTANT for you to know.

Above we've noted that the Surface applied panel is easy and fast to install, with a 10-15 minute installation time. As far as Surface Applied panels go, that's fast. But the truth is, Cast in Place Panels take virtually No time to install! The only time taken to stall this panel, is the time it takes you to place it on the concrete and press it down. THAT'S IT! You trowel AROUND the panel, you don't have to put a finish on the concrete area where the panel lies, so the time saved makes it a complete wash. Resulting in virtually NO TIME to install.

In contrast to this installation, the Surface Applied panel requires you to mark out the area for the DWP to be placed, sweep or blow off surface to prepare, caulk the back of the panel before placing on concrete, drill holes for anchors, install anchors & finally caulk perimeter. As you can see, although 10-15 minutes is a fast install time, it is 100% more costly in time.

In most cases, Cast in Place & Surface Applied MATERIALS will be close in price. But if there is a difference, the Surface Applied Panel will cost a bit more, because the adhesive included is expensive. So, Materials & Labor, will always be a Lower Cost with Cast in Place.

Always Seek to install Cast in Place during your concrete pour when its an option. And when bidding, bid accordingly.

To request more information about our products and services, call for immediate assistance 401-473-5584 or mail us at info@dwpnow.com.